A team of students from the University of Glasgow have accomplished a new high with 3D printing- creating the world’s first functional 3D printed jet engine.

This group of students, calling themselves the JetX group, have been developing this engine since 2013. They are the finalists at the 3D hubs student grant and have demonstrated through their work that engineering isn’t all about theory but also has real world practical implications.

This student-led interdisciplinary team of over 50 engineers developed the first X-plorer 1 model collaboratively with Rolls Royce with another advanced model in the works.

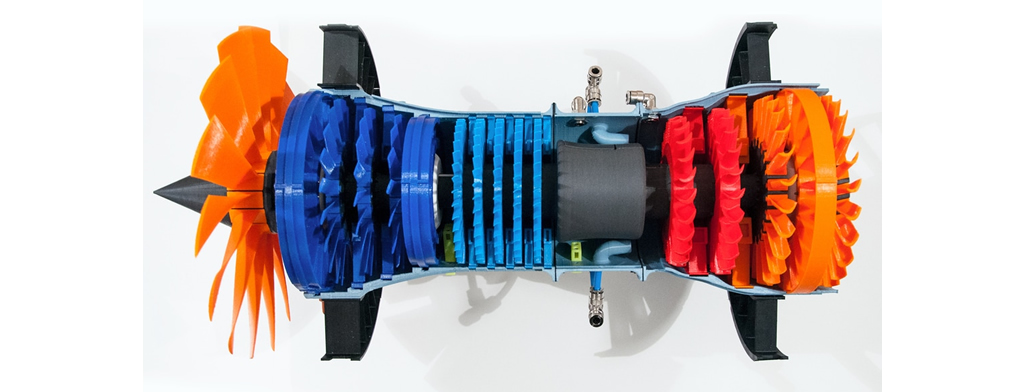

The X-plorer 1 model consists of 800+ parts, of which 515 are 3D printed. The student engineers used Fused Filament Fabrication (FFF) technology to print all their parts using a variety of materials like ABS, PLA, PETG, Nylon and more for various parts of the jet engine.

Each and every part, whether 3D printed or not, has been precisely made to ensure that it meets all the criterion of the existing aero-propulsion theories. This has been an incredible learning experience for all the student engineers working on the project.

JetX used a desktop FFF(FDM) 3D printer to print all the parts for the engine. As against traditional manufacturing methods, 3D printing offered the students a considerable cost reduction.

For the students at JetX, 3D printing the parts was the obvious choice as it allowed them to adjust parts as and when needed. Chris Triantafyllou, the President of JetX, says,” It took 21 prototypes and only seven days to get to the part we needed, using another manufacturing method would have meant months and the cost would be £1,000’s or even £10,000’s.”

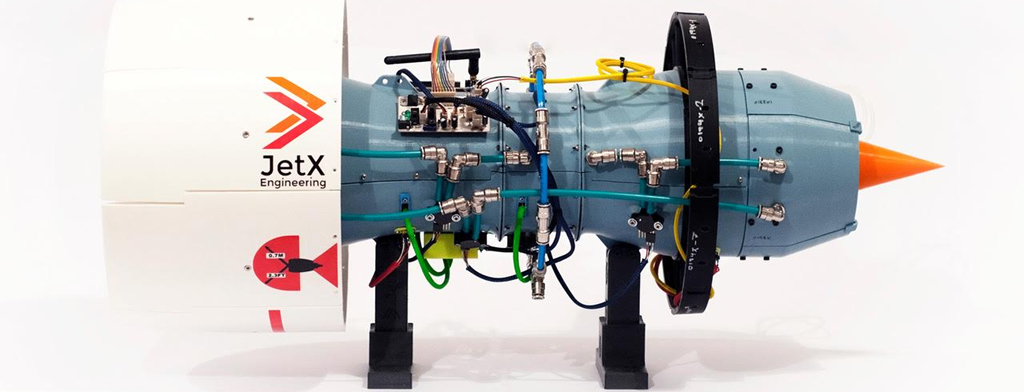

Inside the X-plorer 1, the students have custom-built an Engine Monitoring System(EMS) which includes purpose built software, a wireless transceiver, micro controllers an in-house PCB design and other components needed for analysing the compressed air that passes through the engine. With this, they can monitor the performance of the engine and make the necessary adjustments to the parts and components whenever necessary.

Triantafyllou now aims to further improve on the success of the X-plorer 1 with the continuous support of Rolls Royce and their sponsors. For the students working on the project, it is a immense opportunity to solve real world issues while also getting industry exposure.