Generally, whenever we needed spares, we got them easily from the neighbourhood mechanic or spare part distributor. This was (and is) in the time when casted parts rule(d) the roost. However, times have changed now. For older cars, airplanes and other machinery, you sometimes do not get the necessary spares that were once available freely in the market.

If this was the case, those who needed the spares urgently would contact the manufacturer or other mechanics to see if they had the spares. If this too wasn’t possible, then you had to get the spares custom made for yourself at a foundry who has specialised knowledge in the same. However, this would be a long drawn process where the spares would be needed to be redrawn, prototyped and produced according to the requirements.

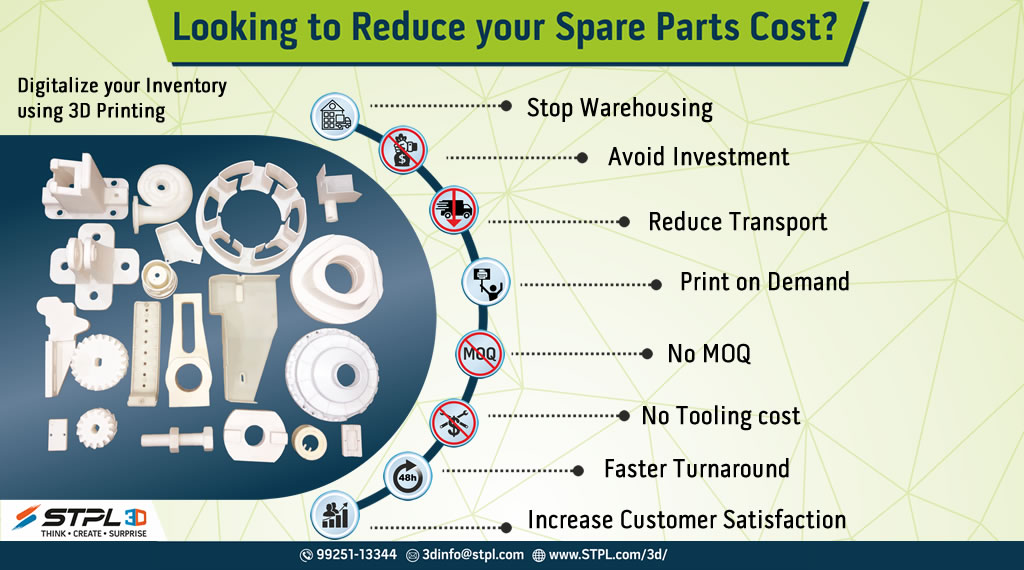

Where STPL3D printing can help

With the help of STPL3D printing, you can just get the spare part ‘printed’ and can continue with the repairs of the old car or machine. This will help you in many ways-

Reduction of costs- This is obvious isn’t it? If you have to make your spares from scratch and if you do it the conventional way, it will cost you a bomb. However, with STPL3D printing, all those costs relating to prototyping and other works gets eliminated, giving you a significant reduction in costs.

Saves a lot of time- With STPL3D printing, you can save a lot of time as you do not need to consult with various parties to search the market for those spares. Instead, you can get it made by just getting it virtually recreated and printed in no-time and with a quality that is much better than the original.

Avoidance for the need of warehousing- If you can yourself produce the 3D parts, why would you need to buy them in bulk or buy raw materials in bulk to produce them? All that needs to be done is to give the virtual designs to the 3D printer in a format it can understand and the printer will get the part made in the shortest time possible.

Easy post-processing- If the part that is to be made is of bigger proportions, making it conventionally would take forever. However, with STPL3D printing, all you need to do is to just virtually design and break up the part into parts which the STPL3D printer can print and then assemble them simply by just sticking them together. You can either use the 3D part as it is or use the plastic STPL3D part to cast the part.

Reduction in transportation costs- If the parts to be made can be made in-house or can be assembled at site, this can obviously lead to a greater reduction in transportation costs. If the parts are large, you do not need to hire big trailers to get the parts to the destination, disassembled parts can be a godsend for you as it can be transported much easier.

Greater customer satisfaction- With a reduction in cost, time and warehousing, there is no doubt that the customer in question will always prefer 3D printing spares the next time he needs it. Even if they are available in the market, such customers would prefer using 3D printed parts due to their superior quality and make.

There is no doubt that 3D printing is fast becoming the next big thing in manufacturing. People are now seeing 3D printing as a way to print all kinds of products whether for industrial, commercial, entertainment or medical use. In future, there will be a day when a 3D printer will be as ubiquitous as a fridge, washing machine or TV in every home. 3D printing has the ability to transform the way people live their lives.